Electric Cremator DFW Electric Cremation Furnace

Electric cremator

In November 2018 we launched the DFW Electric, electric cremator. The DFW Electric makes it possible to cremate completely sustainably, without the use of gas. The oven can even run completely climate-neutral when the crematorium uses, for example, wind and or solar energy. Partly due to geopolitical developments in recent years, it is necessary for companies to get rid of gas, for crematoria the DFW Electric offers a solution. After the launch in November 2018, the first DFW Electric was put into operation at Crematorium Nedermaas in Geleen in June 2019. In December 2022, 25 electric cremators spread across England, Germany and the Netherlands are in operation. 11% of the Dutch crematoria are already equipped with electric cremators. It is expected that the Netherlands will have 118 humane crematoria by the end of 2023. And that 16% of those crematoria will be equipped with electric cremators. In the coming years, more and more electric cremation ovens will be installed in various European countries in order to meet the climate goals. In 2030, about 50% of the crematoria will be equipped with an electric cremator. All new installations to be built will then be electric.

How does the DFW Electric cremation furnace work

The DFW Electric looks the same as a gas oven in the insertion room. Most crematoria have an automatic inserting machine (AIM) with which the coffin (or shelf) with the deceased is entered into the oven in a dignified manner. After the coffin has been inserted into the DFW Electric, the cremation starts. An electric cremator is always kept at temperature with the aim of having enough energy available in the oven to start the cremation process. With the energy present in the body and the coffin, the cremation process is completed and the oven is kept at temperature for the next process. If more than 2 processes are carried out per day, the oven itself does not consume any electrical energy during the days that it is cremating. Only the filter system uses electrical energy. Because the DFW Electric uses the energy very efficiently, the cremation process requires 20 minutes more time. A cremation process in the electric cremator takes an average of 110 minutes.

Ash deceased after electric cremation

The ashes that remain after a cremation in an electric cremator look exactly the same as with a cremation in a gas oven. After cremation, the ashes are processed into fine granules in a Cremulator. First, the ash is separated from any metals present such as surgical metals. These metals are collected by the crematorium and picked up by a processing recycling company.

Sustainable electric cremation

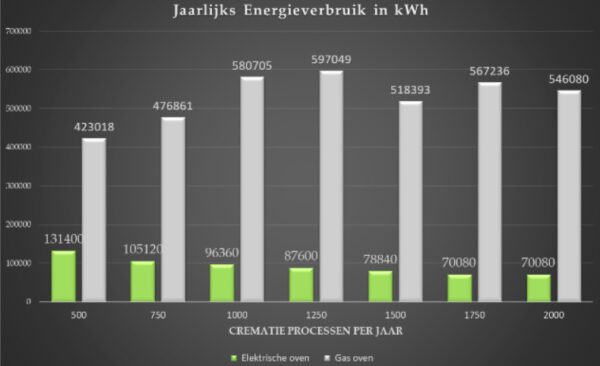

The DFW Electric uses approximately 85% less energy than a gas oven. This makes the DFW Electric more sustainable and also saves on the energy costs per cremation. The following graph shows the total energy consumption of the furnace and filter installation together.

There is no emission from the burners and because the process is quieter, the temperature peaks are lower. This results in a 50% lower emission of NOx (Nitrogen Oxide). Because the temperature fluctuations in an electric cremator are smaller, (the oven is always kept at temperature), the wear and tear on the refractory brickwork is lower. As a result, the brickwork lasts longer so is making the oven more sustainable in maintenance. When burning 1 m3 of gas, 1 liter of water is released. Because there are now no burners present, less moisture passes through the filter system, which benefits the lifespan of the filter parts. Also with the electric cremator, the thermal energy that is released when cooling the flue gases can be used to heat the building. The noise level of the electric cremator is so low that it is almost not noticeable that a cremation process is running. When the energy is generated by 200 solar panels, the oven can be climate neutral in operation. With another 100 solar panels, the filter system can also be supplied with energy.

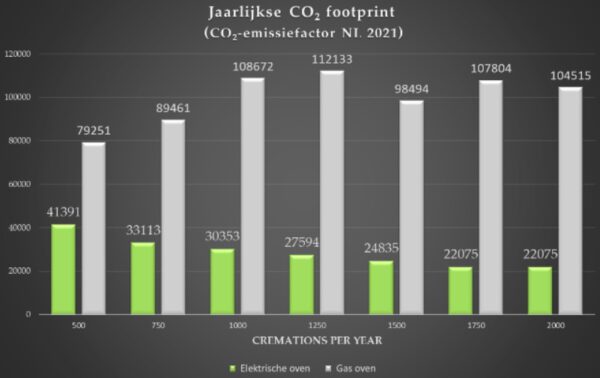

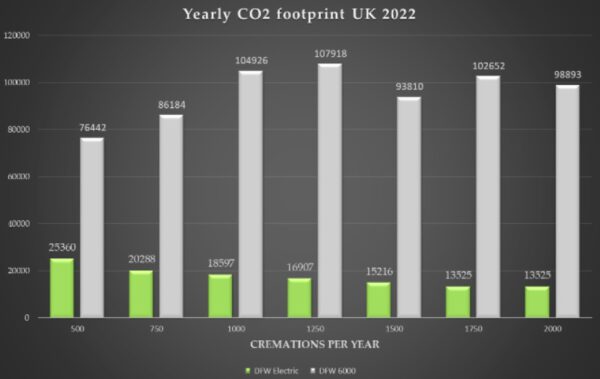

The following graphs show that even when using the current energy mix from the electricity grid, CO2 emissions can be reduced by more than 80%. These graphs differ per country because the CO2 footprint of the energy mix differs per country.

Technology DFW Electric

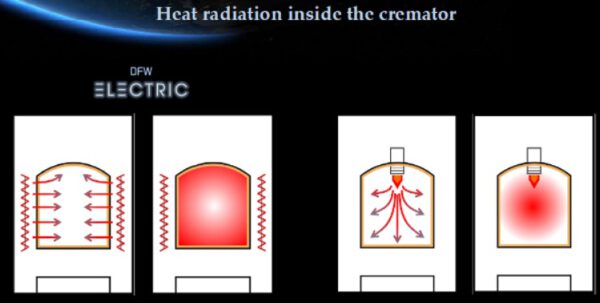

The oven is brought to temperature by electrical elements. The elements are protected, by the silicon carbide brickwork, against the flue gases to achieve an expected service life of 8000 cremations. Replacement of the elements can be done from the outside of the oven without damaging the masonry. Silicon Carbide allows the heat of the elements to pass through very well. The permeability of the heat can be compared to the heat of the sun which radiates very easily through glass. With a minimum starting temperature in the afterburning chamber of 700 degrees Celsius, the emission requirements in the field of carbon monoxide, particulate matter, dioxins, hydrogen chlorides, nitrogen oxide, hydrocarbons, sulfur oxides and mercury are met. The following image shows schematically the heat build-up in an electric cremator.

The thermocouple measures current in the middle of the volume. That is the hottest place in the gas oven. Therefore, the temperature in the afterburning chamber in a gas-fired installation must be kept at a minimum of 800 degrees Celsius in order to meet the emission requirements. If a gas-fired installation preheats on a Monday morning and the thermocouple measures 800 degrees Celsius, the temperature will drop more than 100 degrees within 5 minutes when the burner goes out. In an electric cremation oven, the heat comes from the brickwork. When the elements go out, the temperature drops less than 5 degrees in 5 minutes.

Future of cremation

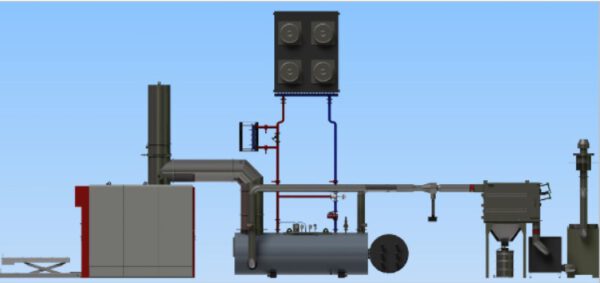

At the moment, for a crematorium that does not cremate 24 hours a day, the electric cremator is the most sustainable cremator. Even when using the current energy mix from the electricity grid, CO2 emissions can be reduced by more than 80%. A gas oven can be converted to various fuels. Bio Propane is a possibility, then the CO2 Footprint is reduced by 80% compared to natural gas. With Bio Propane you have to take into account “Mass Balance” so that 100% reduction is not realistic. Green electricity will also have to be purchased for the required electrical energy for the filter system and control technology. Hydrogen is also a possible fuel. However, at the moment it is still the case that it costs 2 kWh of energy, for production and storage, to be able to supply 1 kWh of energy. Hydrogen does not occur freely in nature. In addition, most of the hydrogen for industrial use is made of natural gas. The flame temperature of hydrogen is higher than that of natural gas, which leads to a higher NOx emission when you burn hydrogen. The residual product water that is released after combustion has no positive influence on the life of the filter system, due to the acidic flue gas components of the cremation process. In addition, when burning Bio Propane or Hydrogen, the total energy consumption will remain higher than with the electric oven installation. When burners are used, air (oxygen) will have to be added. This means that when heating, a stream of air and flue gases moves through the oven installation. In other words, energy is destroyed. An electric oven is shut down during heating. The heated air stands almost still. That is why it is currently wiser to use Bio Propane and Hydrogen to generate electricity to reduce the CO2 emission factor of the electricity grid. This has a positive impact on everything that is connected to the electricity grid including the electric cremator. It is expected that all existing gas-driven cremators will be replaced by electric ovens. Overview DFW Cremation installation with fixed bed filter system.

DFW Electric: the electric cremator

Download here the product flyer of the DFW Electric cremator (pdf)

Or see here the placement of two DFW Electric cremators in the electric crematorium of Lugano.