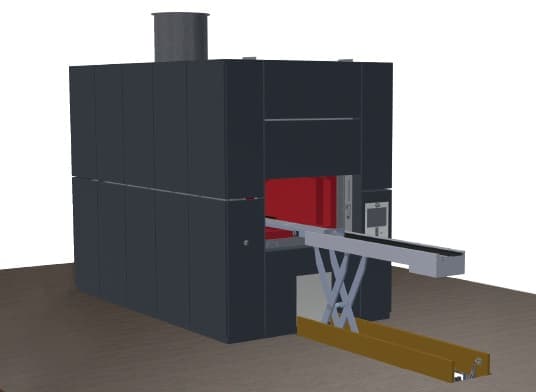

Launch DFW electric cremator

The DFW Electric cremator is the latest addition to the DFW range. It will be known by the shorter name DFW Electric. The power for the electric cremator is provided by the electricity network but can also (partly) be generated by, for example, solar panels. For that reason, the DFW Electric can be considered an environmental friendlier, more energy-efficient than the standard gas-heated cremator. Thanks to this green energy, it works in a CO2 neutral way. The DFW Electric is a ‘hot insert’ cremator and is designed as a ‘single-end’ cremator. To reduce the assembly time on site, the cremator is delivered fully assembled.

Automatic insert machine

The DFW Electric has an Automatic Insert Machine (AIM). The electric cremator has been designed in such a way that the AIM can be integrated into the floor in front of the cremator. This makes it possible to completely keep the AIM out of sight when it is not used. This youngest cremator is equipped with the OMR control system, which makes the Cremulator, the AIM and the downstream filter installation very easy to operate. The cremation process parameters can simply be changed, if needed, via the touch screen. It is also possible to assist you through the internet if changes need to be made to the cremation process.

Ergonomics DFW electric

The Ash pan containing the remaining ashes is moved to an ergonomically responsible position with a lift system. Taking out the ash pan is now so much easier for the operator as a result.

Energy costs

The energy consumption of each cremation can be viewed via the optional report system. The energy costs are expected to be less than those of a gas-heated cremator. The reliable continuous measurement of O2, temperatures and low pressures ensure a constant cremation process.